CONDOR short module type T

with threaded joint

FOR BURSTLINING

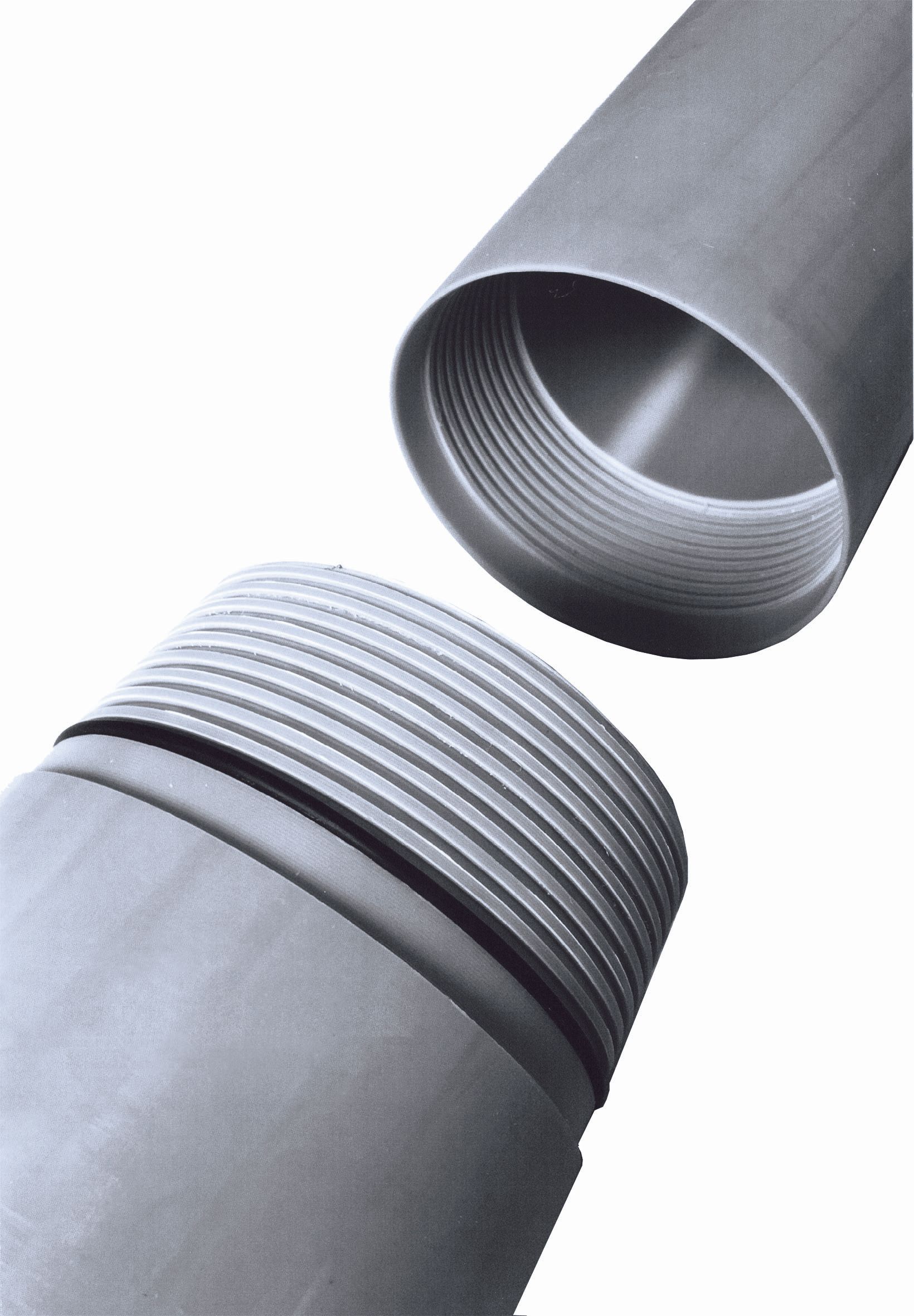

The CONDOR short module type T is a short pipe made of Polypropylene (PP) pipes with a conical screwed joint equipped with an O-ring seal (NBR and EPDM). The bell and the spigot are machined into the pipe wall. The module ends protrude neither outwardly nor inwardly.

If maximum pulling force is required, decide for the CONDOR module pipe type T!

THE BENEFITS OF THE CONDOR SHORT MODULE TYPE T

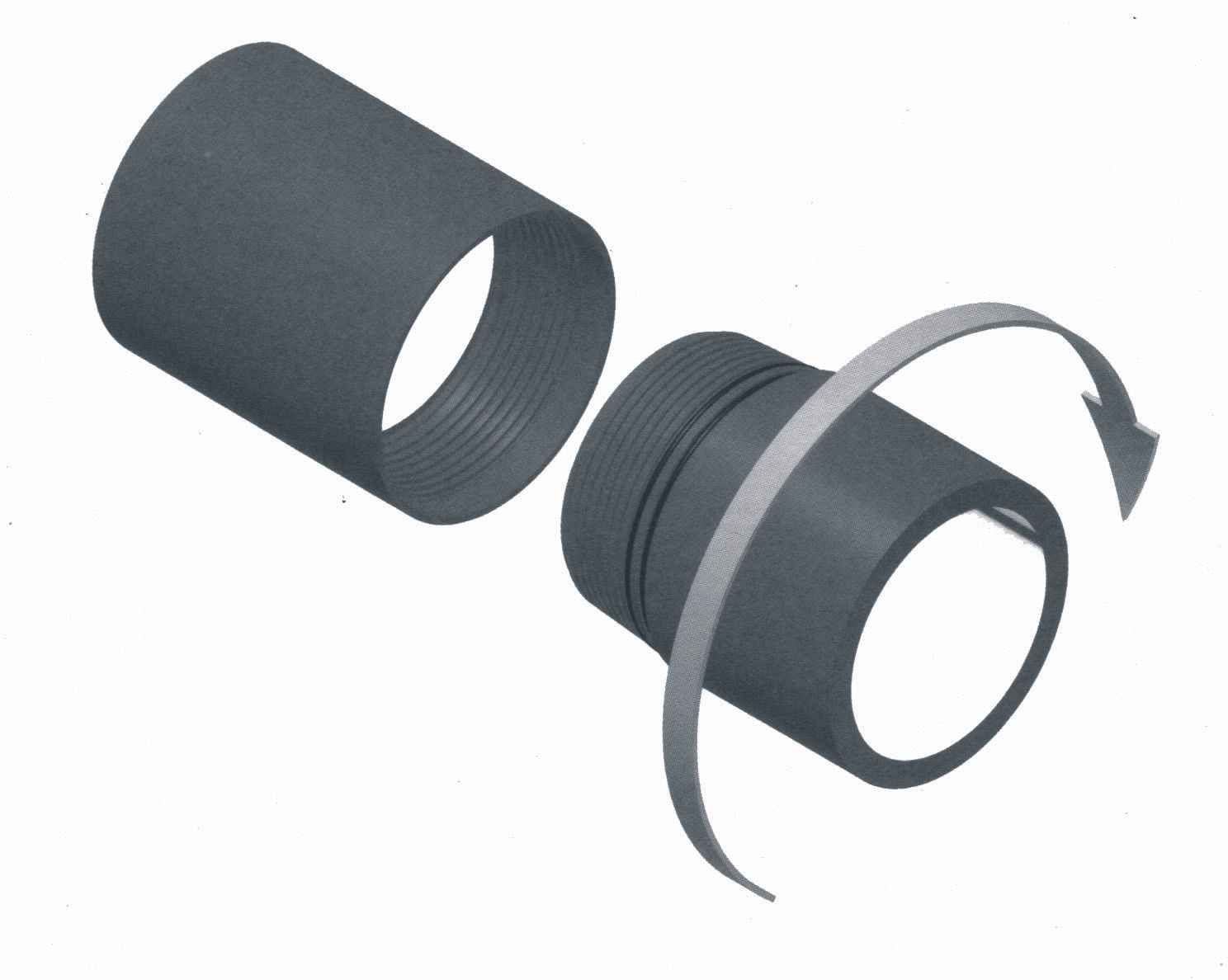

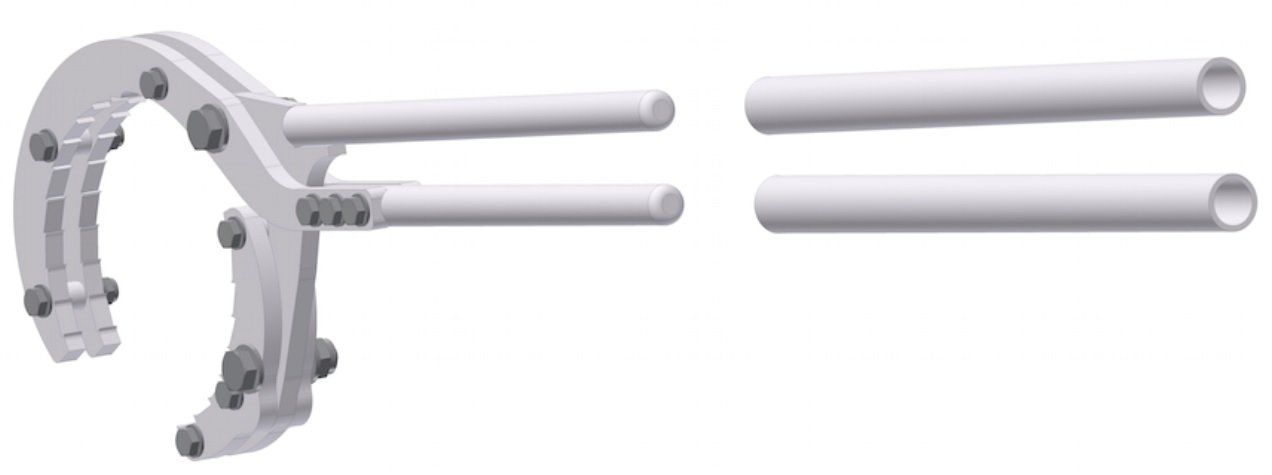

- assembly manually by hand tools only (gripper tool, strap wench)

- back-support for the new product pipe is not needed during the installation

- assembling in round shafts or starting pits of minimum ID 800 mm possible

- high pulling forces, see test scheme

- pipe connections are tight up to 3.5 bar internal pressure

- joined module ends protrude neither outwardly nor inwardly

Joint system:

- conical screwed joint with O-ring seal

- insertion depths:

- up to OD 200 mm: 75 mm

- up to OD 400 mm: 95 mm

- construction length/total length: 0.50 m/0.60 m, and 1.0 m/1.10 m

- other lengths on request

- PP pipe according to DIN 8077/78 and DIN EN 13689

- OD 110 mm to OD 400 mm, colour: gray

The pull- and tightness tests are carried out in co-operation with the Danish Technological

Institute. The short module pipe program is tested according to the standard regulations for gravity sewer pipes. The tightness of the threaded joint was tested with an increased internal pressure of 3.5 bar throughout 2 hours.

Site assembly:

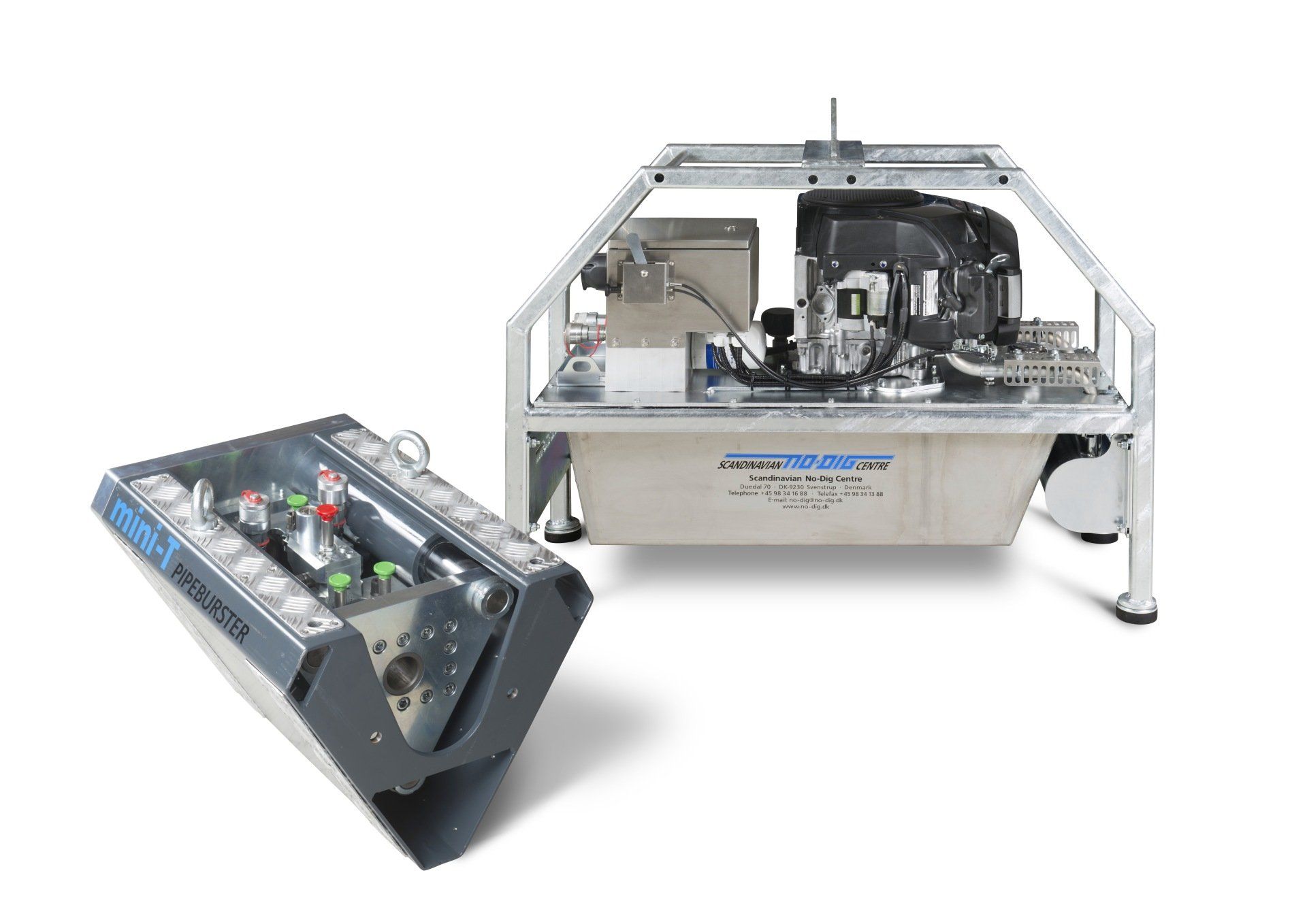

First the burst machine is placed in the shaft resp. construction pit. Then the steel rod is pushed throughout the old pipeline up to the starting pit and the pulling head will be connected. First the adapter module is clamped into the pulling head and the assemblying of the short module can start. The first short module will be twisted by hand into the adapter module. The tightening is made by the help of a special gripper tool or strap wench (only for OD 110 and 200 mm). After the short module are tightened no gap between the screw connection should be visible. Then the static pulling unit pulls the short module into the old pipe. Only the sleeve end of the short modules has to be visible in order to connect the next short pipe by twisting. After all short module pipes have been inserted, the new pipeline is completed.

The static pulling unit will be supported by a plate system avoiding damages of the shaft wall.

For the static burst machine and gripper tools please contact SCANDINAVIAN NO-DIG CENTER.

Institute. The short module pipe program is tested according to the standard regulations for gravity sewer pipes. The tightness of the threaded joint was tested with an increased internal pressure of 3.5 bar throughout 2 hours.

Site assembly:

First the burst machine is placed in the shaft resp. construction pit. Then the steel rod is pushed throughout the old pipeline up to the starting pit and the pulling head will be connected. First the adapter module is clamped into the pulling head and the assemblying of the short module can start. The first short module will be twisted by hand into the adapter module. The tightening is made by the help of a special gripper tool or strap wench (only for OD 110 and 200 mm). After the short module are tightened no gap between the screw connection should be visible. Then the static pulling unit pulls the short module into the old pipe. Only the sleeve end of the short modules has to be visible in order to connect the next short pipe by twisting. After all short module pipes have been inserted, the new pipeline is completed.

The static pulling unit will be supported by a plate system avoiding damages of the shaft wall.

For the static burst machine and gripper tools please contact SCANDINAVIAN NO-DIG CENTER.