The Sliplining method

Trenchless rehabilitation processes are very popular and mainly used for the rehabilitation of defective old sewers, where a cross-sectional reduction is possible. One of the most efficient and proven renovation methods is the sliplining process with HDPE and PP short modules with snap-lock and screwed joints. Already about 30 years ago CONDOR invented this renovation method.

In this case the defective old pipes are renewed with smaller pipe inside diameters. In recent years, it has been proven that plastic pipes are ideal for this rehabilitation methods. Old sewer pipes of all materials can be renewed quickly and economically with this short module renovation system. It's not just a repair, it's a replacement of new self-supporting pipelines.

HDPE high quality standard pipes according to DIN 8074/75 and DIN EN 12666-1 and PP pipes according to DIN 8077/78 and DIN EN 13689 are used only for CONDOR short modules.

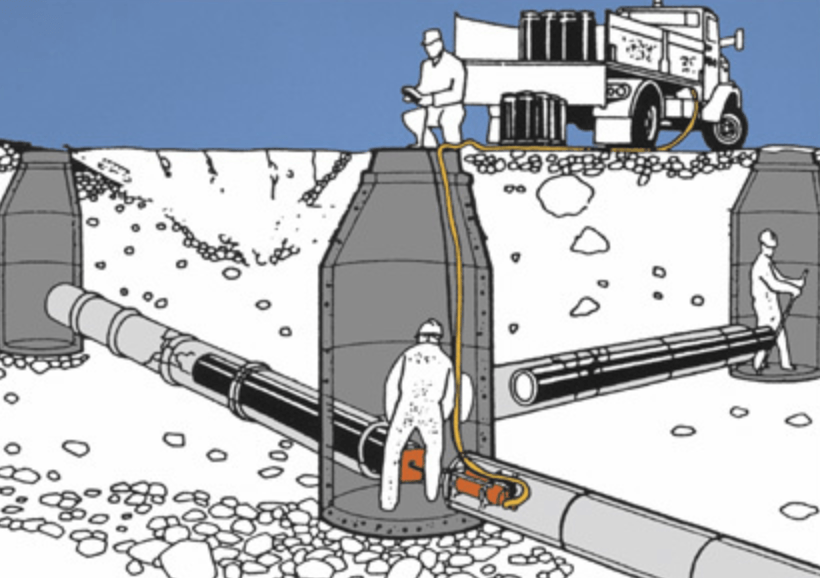

INSTALLATION TECHNIQUE

Before starting the installation, the old pipeline must be cleaned and all protruding sockets of the old pipe have to be removed. Afterwards, it should be ensured that the required cross-section is available. For this purpose, a calibration should be performed with a caliber whose outer diameter corresponds to that of the new pipe diameter.

After a successfull calibration has been completed, the new CONDOR short modules can be assembled and inserted into the old sewer pipeline. The operation can be carried out from

i.e. an existing shaft or construction pit to the next service shaft.

- fast execution time

- no traffic obstruction

- no disturbances of local residents

Due to the ever increasing safety and maximum service life requirements in the industrial sector, CONDOR also offers electrofusion short modules as an alternative to the snaplock and threaded short modules.